Contents

Resource 1: Chemical Inventory: Identifying Chemicals in Products and Processes¶

Goal¶

To identify the chemicals used to produce and manufacture a product, including those chemicals that remain in the product when used and any chemicals that are produced after use a./or during waste management treatment.

Introduction¶

To complete a chemical inventory, you’ll have to learn which chemical substances are present in the final product, which are used to make the product, and what breakdown chemical substances are likely. A chemical inventory considers the chemicals used to manufacture a product because they may remain in the product and workers and potentially the local community are exposed to those chemicals. It is also important to think about what the chemical may become when it is released to the environment. Many chemicals degrade into other chemicals or ultimately break down to CO2 and water over time.

Ideally, it would be possible to know all of the reagents, catalysts, auxiliaries, products, by-products, residuals and emissions at each life cycle stage. However, gathering this information is not always a simple task. The more you know about what is in the material, the better you can identify areas for improvement.

Keep in mind that even small amounts of toxic chemical ingredient additives can greatly impact the sustainability attributes of a product. Additives to plastics and residual chemicals from manufacturing can:

- Affect recycling, incineration and value-recovery options

- Be hazardous to workers or the environment

- Leak into the environment after disposal

- Affect the quality of recycled materials and how they can be used in future products

What are the life cycle stages you plan to evaluate?¶

At a minimum, you will want to know the chemicals that are present in the chemicals, materials or products at the life cycle stage that you control and in the product that you are making to sell to customers. This would include the base material along with known additives. It should also include residuals and impurities above a desired threshold.

What chemical types do you plan to evaluate?¶

For some products, you may want to focus on certain substance types or functional uses. For example, while there may be many residual substances in a laptop casing, the presence of flame retardants may have sustainability implications. Likewise, there may be concerns about the type of preservative used in a surfactant.

What concentration thresholds will you use?¶

Commonly used strategies include identifying all chemicals that are intentionally added to the formulations, material or product at any concentration or produced regardless of the concentration. Others will set a reporting threshold such as 0.01% (100 ppm) or 0.1% (1000 ppm) for reporting both intentionally added and residual substances. Others may inventory chemicals at different thresholds depending on the likelihood of concern. For example, safety data sheets require reporting of carcinogens at 10x lower concentrations (0.1%) than other chemical hazards (1%).

Using a chemical inventory template, identify all of the chemicals used at each life cycle stage that you evaluate. Identify the concentrations thresholds or other rules used to decide which chemicals to include in your inventory.

What chemicals are likely to be present in the product based on what you know about production and manufacturing of the product? Identify any concentration thresholds or other rules used to decide which residuals or impurities to include in your inventory.

Which of the above resources have you used to identify chemicals in your product or chemicals that may formed when the product is used or no longer needed?

Example¶

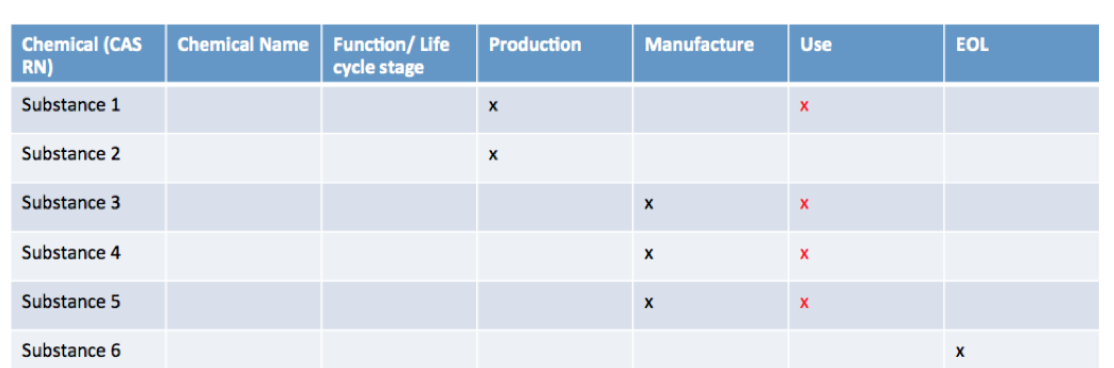

Chart template for creating a chemical inventory and mapping chemical use to life cycle stage.

image

Tools¶

Some organizations offer tools for assisting with building, storing, and using your chemical inventory. These are typically focused on the constituents of the product (use phase inventory) and do not necessarily have space by default for inventorying process and byproduct chemicals. Both of these tools will automate list screening hazard assessments, as well. - Pharos Chemical and Material Library - toxnot.com